Fabric Quality Control

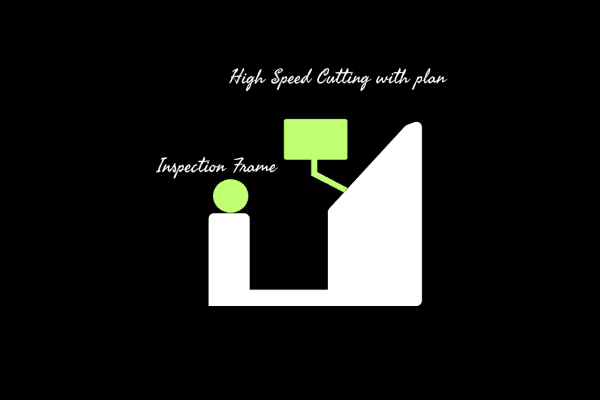

Our system streamlines quality control by logging faults and guiding inspections, feeding data into an optimization engine that creates the best cutting plans.

Quality control is the most labor-intensive aspect of textile production. Manual inspections without proper process controls can lead to significant losses. Our system enables operators to log faults and guides them through the inspection process to improve accuracy. The data collected is then analyzed to drive better decision-making. This information feeds into our optimization engine, which generates the most efficient cutting plan based on fault distribution and customer-defined rules. The outcome is fewer short pieces, reduced B-grade fabric, and improved yield, increasing departmental efficiency by up to 0.4%.