An end-to-end solution designed for the fabric folding quality control department. The system is designed to cover all of the operations of both woven and non-woven fabric specifically denim, dyed, printed, and greige.

The system operates by enabling the operator to enter fault details directly into the system using a Fault Marking Keyboard and electronic meter to fetch meters. The system saves operational costs by 25%.

The system is also linked with the in-depth analytics system, which enables the management to make informed decisions. Using multiple filters, the managers can identify faults with respect to the department, suppliers, and process

Salient FeatureMultilingual support built into the application interface enables the operator to achieve efficiency through comfort/ease of use.

Salient FeatureArchiving data into organized sections allows one to navigate quickly and make informed decisions in real-time

Salient FeatureArchiving data into organized sections allows one to navigate quickly and make informed decisions in real-time

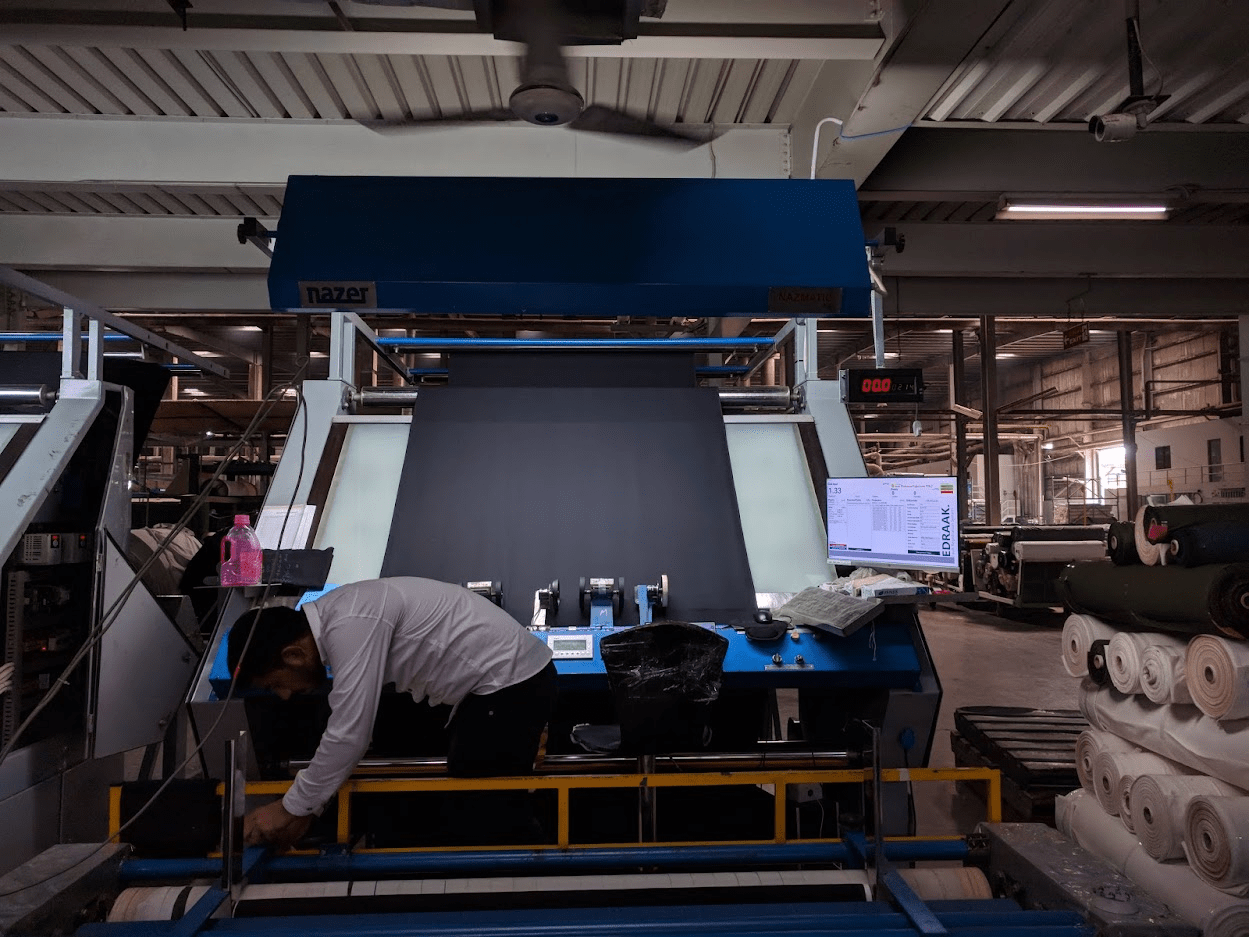

Salient FeatureIntegration of multiple sensors with your machine, to be able to extract more out of the system.

sensors such as weight, width, marking can be connected

Edraak systemsGallery

Edraak SystemsFacts & Figures

140 Million Meters Processed

Saved 356 Million Liters of water

Saved 260 Trees

140 Million Meters Processed

Saved 356 Million Liters of water

Saved 260 Trees

Edraak systemsClients

Edraak systemsGet A Quote

Send us Message

Visit our offices or simply send us an email anytime you want. If you have any questions, feel free to contact us.